Top 5 Snack Packaging Bag Types for U.S. Brands in 2025

Home » Other flexible packaging knowledge » Top 5 Snack Packaging Bag Types for U.S. Brands in 2025

1. Introduction: The Rise of Custom Snack Packaging in the U.S.

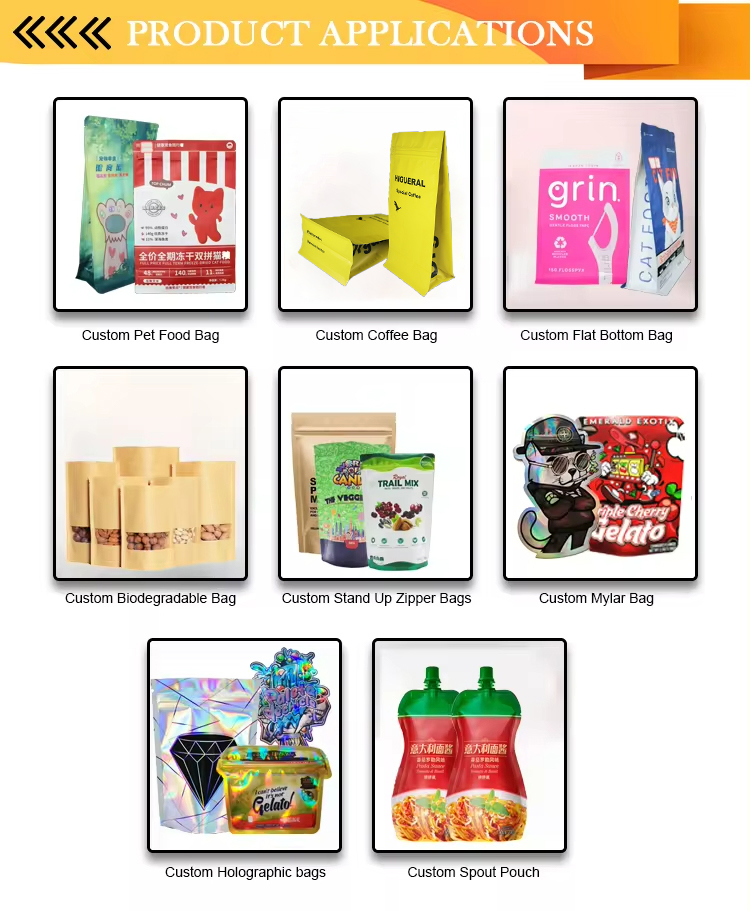

As consumer demand grows for healthy, portable, and visually appealing snacks, U.S. brands are seeking more custom snack packaging options than ever before. From protein bites to trail mix, packaging isn’t just functional — it’s a core part of the brand experience.

For snack food packaging suppliers in the USA, this means staying ahead of packaging trends and offering flexibility, especially for small and mid-sized food producers. Many American brands are now partnering with overseas manufacturers, like JY Flexpack, for custom printed snack packaging solutions at competitive prices.

2. Why Packaging Matters in the Snack Industry

Snack packaging isn’t just about protection — it’s about branding, shelf impact, consumer convenience, and compliance.

Good snack packaging must:

Keep contents fresh and moisture-free

Allow easy opening and resealing

Showcase branding through high-quality custom printing

Work with various distribution models (retail, DTC, vending)

Be cost-effective for both small and large batches

With that in mind, let’s explore the top 5 snack bag types in 2025.

3. Top 5 Snack Packaging Bag Types for 2025

3.1 Stand-Up Ziplock Pouches

These are the most versatile and popular snack bags in the U.S. today. Perfect for granola, dried fruit, or nut mixes, stand-up pouches feature:

Bottom gussets for shelf stability

Resealable ziplocks

Full-surface custom printing

Matte or gloss finishes

As a small snack pouch packaging manufacturer, we’ve seen a major increase in demand for low-MOQ orders from startups and boutique brands using this format.

3.2 Pillow Bags

Commonly used for chips and puffed snacks, pillow bags are cost-effective and easy to fill using high-speed vertical form-fill-seal (VFFS) machines.

While typically less premium in appearance, pillow bags remain the top choice for large-volume, budget-conscious brands.

3.3 3-Side Seal Bags

These flat pouches are ideal for slim snacks like protein bars or fruit strips. They’re often used by private label snack brands looking for minimalist design and fast production.

3.4 Laminated Roll Film Packaging

Laminated snack packaging roll film is used for automatic pouch forming and sealing. It’s the go-to solution for high-output snack factories.

Features include:

High-speed machine compatibility

Multiple film structures (PET/PE, BOPP/CPP, PET/AL/PE)

Custom printing on rolls (up to 10 colors)

Cost-efficiency at scale

Our factory supports custom roll widths, unwind directions, and perforation requirements for different snack machines.

3.5 Custom Printed Pouches (Brand-Centric)

For brands aiming to stand out, custom printed snack packaging is essential. We offer:

Digital or gravure printing

Metallic, kraft, or biodegradable films

Gloss-matte combo finishes

Window or no-window options

Whether you’re launching in Whole Foods or selling via Amazon, professional printing boosts shelf impact and builds trust with consumers.

4. Choosing the Right Snack Food Packaging Supplier in the USA

Finding a snack food packaging supplier in the USA isn’t always easy — many local vendors have high MOQs and long lead times.

That’s why U.S. brands increasingly turn to reliable overseas factories with:

FDA-compliant materials

Transparent pricing

Fast production turnaround (10–15 days)

Low MOQs for startups (as low as 5,000 bags or 200kg roll film)

5. How Small U.S. Brands Can Work with Overseas Manufacturers

If you’re a small snack business or launching your private label line, working with a small snack pouch packaging manufacturer overseas can be a game-changer.

Tips for working smoothly:

Choose a factory with English communication support

Request free structure samples before bulk orders

Confirm bag formats and machine compatibility

Ensure packaging meets U.S. food contact compliance standards

6. Why JY Flexpack Is a Top Snack Bag Factory for Private Label Projects

At JY Flexpack, we’ve worked with U.S. snack brands of all sizes, from Amazon sellers to regional retail startups.

Why we’re trusted as a snack bag factory for private label brands:

10+ years experience in food-grade flexible packaging

BRC, ISO, and FDA-compliant production

In-house lamination and gravure printing

Rapid sampling & small batch customization

Dedicated export team for the U.S. market

Whether you need laminated roll film for snack automation or printed pouches, we deliver fast and with precision.

📩 Contact us now for a free quote:jinyibaozhuang1@163.com

7. Conclusion: Plan Your Snack Packaging Upgrade Today

The U.S. snack industry is growing — and so is the demand for flexible, brand-driven packaging. Whether you’re a startup or an established brand, upgrading your snack packaging can elevate your brand, improve shelf life, and boost sales.